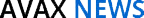

A 3D object called the Quin.MGX is seen at the Belgian company Materialise, the biggest 3D printer in Europe, in Leuven January 24, 2013. 3D printing has already changed the game for manufacturing specialized products such as medical devices but the real revolution will come when designers start to rethink the shapes of objects. Materialise, a pioneer in the process, has a display of a foldable chair printed from one continuous piece of plastic – and made with the hinges already joined together, for example. (Photo by Yves Herman/Reuters)

Kevin Collier scans several small models, which can then be digitally manipulated and 3D printed, at America Makes, the National Additive Manufacturing Innovation Institute in Youngstown, Ohio, March 5, 2014. Along the banks of the Mahoning River in the struggling Ohio steel town of Youngstown sits a once-abandoned furniture warehouse that has been converted into a sleek new laboratory. Inside is a Silicon Valley-style workspace complete with open meeting areas and colorful stools. Several 3-D printers hum in the background, while engineers type computer codes that tell the machines how to create objects by layering materials. (Photo by Jason Cohn/Reuters)

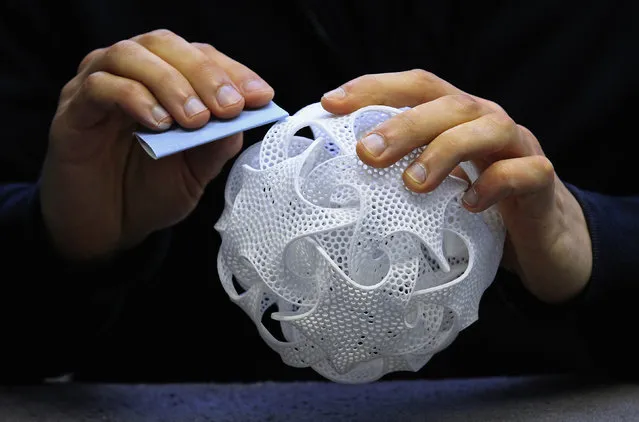

A 3D model of a complex anaplastology case, created in collaboration with the anaplastologist Jan De Cubber, is seen at the Belgian company Materialise, the biggest 3D printer in Europe, in Leuven January 24, 2013. (Photo by Yves Herman/Reuters)

A picture shows figures that were created by means of 3D printing in Berlin, January 7, 2013. The figures are 3D printed representations of the original models that were recorded with 3D scanning technology by Gismo at the Raumfahrtagentur hacker space in Berlin. (Photo by Thomas Peter/Reuters)

TechShop representative Andy Leer maintains a MakerBot Replicator 2 desktop 3D printer at the GE Garage in Washington March 20, 2014. GE Garage space is open from March 24 to April 9 in Washington and offers the chance to explore and learn about how technology is changing the way things are built today. (Photo by Gary Cameron/Reuters)

Seized plastic handguns which were created using 3D printing technology are displayed at Kanagawa police station in Yokohama, south of Tokyo, in this photo taken by Kyodo May 8, 2014. Yoshimoto Imura became the first man to be arrested in Japan for illegal possession of two guns he created himself using 3D printing technology, Japanese media said on Thursday. The 27-year-old, a college employee in the city of Kawasaki, was arrested after police found video online posted by Imura claiming to have produced his own guns. Gun possession is strictly regulated in Japan. Police raided Imura's home and found five guns, two of which could fire real bullets, Japanese media said. (Photo by Reuters/Kyodo)

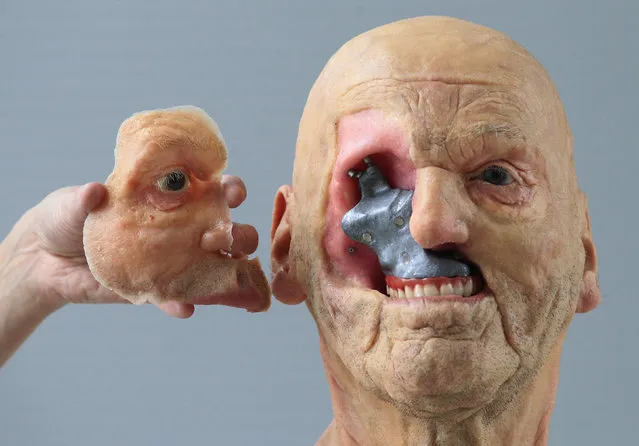

A staff member of Nihonbinary demonstrates their 3D printer MakerBot Replicator 2X as it prints an Acrylonitrile butadiene styrene pylon during the International Robot Exhibition 2013 in Tokyo November 8, 2013. Japanese entrepreneurs are building businesses based on 3D printing, showing the sort of pioneering spirit Prime Minister Shinzo Abe hopes can revitalise a calcified economy. Whether these entrepreneurs can lay the foundations for a new era in Japanese products though may depend on whether Abe can tear down barriers in a wider business culture that shuns risk and supports the status quo. (Photo by Yuya Shino/Reuters)

Intern Jim D'Andrea detaches plastic planetary gears after they were 3D printed at America Makes, the National Additive Manufacturing Innovation Institute in Youngstown, Ohio, March 5, 2014. (Photo by Jason Cohn/Reuters)

[img alt="A technician at Belgian company Materialise, the biggest 3D printer in Europe, operates a laser sintering machine that uses high-powered lasers to fuse particles of plastic, layer by layer, to create 3D objects, at the company's headquarters in Leuven January 24, 2013.

A technician at Belgian company Materialise, the biggest 3D printer in Europe, operates a laser sintering machine that uses high-powered lasers to fuse particles of plastic, layer by layer, to create 3D objects, at the company's headquarters in Leuven January 24, 2013. 3D printing has already changed the game for manufacturing specialized products such as medical devices but the real revolution will come when designers start to rethink the shapes of objects. 3D printing removes the limitations of the manufacturing process from the equation, which means whatever can be designed on a computer can be turned into an object, specialists say. (Photo by Yves Herman/Reuters)

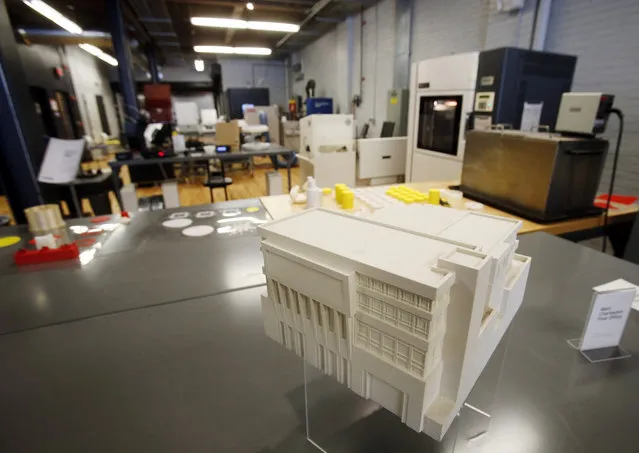

This plastic model of the Charleston, West Virginia post office, was 3D printed and is on display at America Makes, the National Additive Manufacturing Innovation Institute in Youngstown, Ohio, March 5, 2014. (Photo by Jason Cohn/Reuters)

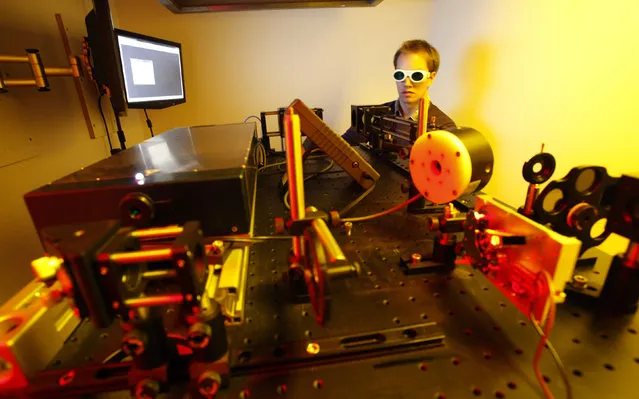

Dissertation student Jan Torgersen of Vienna University of Technology operates a newly developed 3D laser printer, in Vienna March 29, 2012. Torgersen and colleagues have set a new world speed record for creating 3D nano objects. The University team create their grain of sand-size structures in just four minutes, a fraction of the time that other items have previously been printed. Previously making complex large 3D structures would take hours or even days but with the newly developed 3D laser printer the scientists can speed that up by a factor of 500 or in some cases 1,000 times. The process called “two-photon lithography” involves using a focused laser beam to harden liquid resin in order to create micro objects of solid polymer. The scientists said the technique could be developed to make small biomedical parts to be used by doctors. (Photo by Herwig Prammer/Reuters)

MakerBot Replicator 2 desktop 3D printers are calibrated at the GE Garage in Washington March 20, 2014. GE Garage space is open from March 24 to April 9 in Washington and offers the chance to explore and learn about how technology is changing the way things are built today. (Photo by Gary Cameron/Reuters)

Physicist Urs Duerig uses tweezers to hold a silicon tip with a sharp apex, 100,000 times smaller than a sharpened pencil, of a prototype of an IBM NanoFrazor 3D nano printing tool at a laboratory of IBM Research in Rueschlikon, near Zurich April 23, 2014. A laboratory in Switzerland has created the smallest magazine cover in the world, using a tiny chisel to create an image so minute that 2,000 of them could fit on a grain of salt. Scientists carved the 11x14-micrometre image of two pandas that appeared on last month's cover of the National Geographic Kids magazine onto a polymer using technology similar to 3D printing. (Photo by Arnd Wiegmann/Reuters)

Twelve-year-old Leon McCarthy (R) rests his prosthetic hand on a MarkerBot Replicator 2 Desktop 3D Printer, while talking to the company's CEO Bre Pettis, at the new MakerBot store in Boston, Massachusetts November 21, 2013. McCarthy, whose prosthetic hand is made of parts printed from a MakerBot 3D printer, broke a piece of it last week while playing football, so he printed a new finger to repair it. (Photo by Brian Snyder/Reuters)

12 May 2014 10:46:00,

post received

0 comments